How the Safety Box from Webasto monitors air quality in cabins of agricultural and construction machinery

Help me, I am a product, a solution - and now I am looking for a problem. Often enough, companies develop products for which they then have to go to great lengths to find buyers. This is annoying and not always promising. Ideally, potential customers are involved in the development from the beginning or, even better, a customer comes with a specific request for a solution that one would never have thought of before. This is precisely the situation that gave rise to the Safety Box of Webasto.

"A manufacturer of agricultural machinery approached us to connect a category 4 air filter system to the sprayer's air conditioning system. For us, such tasks are part of our daily business," says Marian Culik, Director Product and Service Management at Webasto. For years now, there has been an EU standard for air filtration in the cabs of agricultural machinery.

This standard (EN 15695) describes how filtering must be done and how it should be tested. However, the information on functional safety was missing. But it is precisely here that specifications would make sense. Culik: "If you already install a filter that keeps harmful things away from the driver in the cabin, then you should also make sure that the filter always works."

Monitoring of air filter operation and warning of defects is safety-relevant

It was precisely this project - ensuring correct filter operation and warning measures should something not work –which was on the manufacturer’s mind. In an FMEA analysis, the manufacturer could work out the safety-relevance. The resulting challenge: The air quality had to constantly be monitored with redundant sensors and the cabin crew immediately warned if the filter does not work.

Initially, the Webasto team conducted a safety analysis according to various EN standards. "In the passenger car sector, you would write software with a complicated set of rules, perform tests, and connect this software to hardware comprising redundant system components. But in this case, this procedure would have been far too complex. So, we asked ourselves if it couldn't be solved more simply," recalls Culik.

Simple, fast, and efficient with hardware-based solution

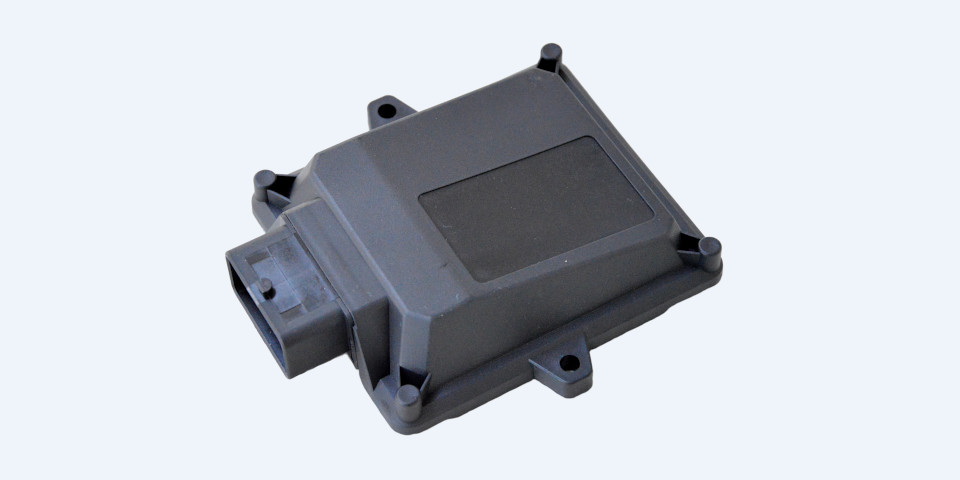

Often, less is more, and so the team at Webasto took a radical, almost "old-school" approach: The development team dispensed the software approach and developed a hardware-only solution that could only do one thing, but particularly well: compare threshold values from several sensors and measure them continuously against a fixed threshold value. If the value of the category 4 filter system is exceeded, an alarm is triggered. Combined with a switch and a pressure sensor and inserted into a waterproof, heavy-duty case, this is how the "Safefy Box" was created.

The safety box is about the size of two cigarette packs. It contains the hardware for monitoring the sensors. This also includes and two redundant LEDs, two red and two green ones, which are installed in the dashboard. If the indicator lights up green, the air filter is working. A red indicator signals: danger of air pollution. This sounds trivial, but a lot of expertise goes into the little box: Culik: "In order for the filter to work and meet the standard, there must be a minimum overpressure in the cabin, and a minimum flow of the filter must be guaranteed. The Safety Box monitors that sufficient outside air is drawn in through the filter into the cabin, and that the required overpressure prevails there so that no substances from outside can penetrate. This is ensured by the pressure switch, a pressure sensor and two flow meters."

Safety Box also relevant for construction machinery

Webasto designed the Safety Box for a specific application in an agricultural spraying vehicle. And that was just the start: "From the very beginning, we sensed we were solving a specific problem that may not even have been recognized in other areas. With our automotive industry DNA, we are acutely aware of safety issues," explains Culik. In the construction machinery industry, there are many areas of application in which the air quality in the cabins is safety-relevant for the operators.

Culik cites, for example, construction equipment at landfills whose personnel can be protected from landfill gases, carbon monoxide and other hazardous substances in the air. The safety box could also monitor the function of the air filtration system during demolition work and for work at special construction sites, for example in chemical plants, and warn accordingly.

Although this standard does not yet exist for construction machinery, manufacturers of construction machinery can already ensure with little effort that personnel can work in a safe way. With the Safety Box, Webasto has developed a product that solves previously unrecognized but existing problems.

The following news that could also interest you

- BlueCool V-PRO Series: a global success story for the Webasto marine team

At first glance, the new BlueCool V-PRO Series Chiller System from Webasto appears as a mere white casing that produces cold water for centralized air…

- From Fighting Cancer to Great White Sharks: Expedition through Africa with Proven Technology from Webasto

Covid-19, unstable political situations, and a tumor: It took a long time for Micha and Sabine from Team Zetroszone to finally continue their journey.…

- Unlocking the secret of durability: How a Webasto Air Top Evo 40 achieved nearly 20,000 working hours in the harsh Canadian climate

A Case of Exceptional Longevity: An Air Top Evo 40 air heater from Webasto thrives in Canadian conditions, with nearly 20,000 working hours—tenfold…

- Electric thermal management in e-buses: the future is now

Busworld Europe in Brussels isn’t just a key trade fair for the bus industry but also a showcase for innovative technologies. Webasto is leveraging…

- Optimal heating in e-buses: the role of high-voltage heaters

E-mobility is advancing rapidly. Often, it’s the less visible technologies playing a pivotal role in shaping the overall experience. High-voltage…